New APEX Industrial Fastening Tools Exceeds User Demands Across Three Categories

DAYTON, Ohio, July 11, 2018 - APEX Tools has introduced a new line of Industrial Fastening Tools that bring increased durability, longer life and better fit to the fastening user who demands performance-oriented solutions. This combination of benefits will ultimately boost productivity and increase operating efficiencies. The new Industrial Fastening Tools product line brings APEX Assembly & Fabrication Tools’ 85-year reputation of dependable durability to the commercial construction industry, as well as other maintenance, repair and operations (MRO) applications across a wide span of industries.

“We take pride in our ability to provide user-focused fastening solutions in assembly manufacturing and we are confident we will do the same with this product line in construction applications” said Vice President and Global Commercial General Manager, Bill Pugh. “Our primary focus has been and continues to be fastening tools. Our assembly tools are used building vehicles, airplanes, appliances as well as supporting many other industrial applications. We are confident that our product performance and brand reputation will extend to construction, MRO and commercial applications across the world.”

This new line of fastening tools was developed after extensive voice of the customer (VOC) work with end-users in the commercial construction, service trades, light manufacturing assembly and general maintenance and repair industries. This study provided the critical quality requirements designed into the products to provide tools that are stronger and more durable, have a longer life and better fit to meet user needs.

“When we studied and identified what users demanded, we utilized our decades of knowledge and expertise in assembly and manufacturing to develop a solution,” said Industrial Fastening Tools Product Manager, Brandon Stumpf.'

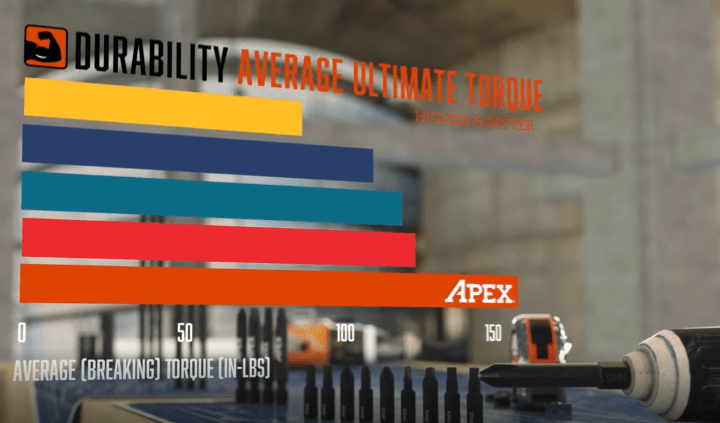

The new Industrial Fastening Tools are made of modified S2 steel to increase durability and strength. The full-bodied bit design provides extra reinforcement and support for the bit tip. To maximize product life, the tools are exposed to a proprietary heat treatment.

“We spent countless hours with our in-house metallurgical team to enhance the heat treatment process ensuring our products meet and exceed user durability and life requirements,” said Stumpf.

The new offering of fastening bits also delivers a superior fit in fasteners and hold tighter tolerance than the competition. Each tool is designed with optimized tip geometry for exact fastener fit, which helps to eliminate cam-out and promotes fastener retention.

The new offering of fastening bits also delivers a superior fit in fasteners and hold tighter tolerance than the competition. Each tool is designed with optimized tip geometry for exact fastener fit, which helps to eliminate cam-out and promotes fastener retention.

The new offering of fastening bits also delivers a superior fit in fasteners and hold tighter tolerance than the competition. Each tool is designed with optimized tip geometry for exact fastener fit, which helps to eliminate cam-out and promotes fastener retention.

The Industrial Fastening Tools line is comprised of bits, bit holders, nut setters, adaptors and sockets in both bulk and retail display packaging combining for over 250 SKUs. The products are available for purchase through APEX’s existing distributor network in different quantities, ranging from two-piece skin cards to 50 count bulk packages.

In addition to the products available at initial launch, APEX Tools will be introducing an innovative new safety product to the commercial construction industry in Q4 2018. This new product will be the first of its kind in the construction space and will launch alongside APEX’s set cases program. The new set cases combine the industry-leading innovation of the APEX Industrial Fastening Tools line with the convenience and accessories needed on hectic job sites to maximize end-user performance.

For more information on the Industrial Fastening Tools line or to find distributors, please visit www.apex-tools.com/industrial.

ABOUT APEX TOOLS

APEX® Tools was founded in 1933 in Dayton, Ohio as the APEX Machine and Tool Company. Since 1933, APEX has been a market leader in fastening tools including bits, sockets, wrenches, and torque products that are engineered for the toughest industrial application and use. APEX Tools and solutions are used in both assembly and MRO (maintenance, repair, operations) applications across the motor vehicle, aerospace, energy and heavy industrial sectors, where they are known for durable dependability.

ABOUT APEX TOOL GROUP, LLC

Apex Tool Group (ATG) is one of the largest manufacturers of professional hand and power tools in the world. ATG serves the industrial, vehicle service and assembly, aerospace, electronics, construction and serious DIY markets.

ATG’s portfolio of over 30 innovative brands includes many category leaders, such as SATA®, GearWrench®, Weller®, Wiss®, Lufkin®, Cleco® and Crescent®. ATG also manufactures select, premier private label mechanics tools.

Across the board, ATG’s brands and tools stand for quality, innovation and value. Known for solving seemingly impossible problems, they are intuitive and simple to use, yet indispensable.

ATG collaborates with distributors, retailers, and large customers across the globe to make sure end users have the tools they need to solve real-world problems.

ATG’s unique category management approach provides customers with end-user data, market research and voice of the customer insight, which helps drive inventory, display and promotion decisions. Plus, ATG’s truly global footprint enables them to serve customers’ needs in a way they would not be able to do if we they a regional player rather than global.